Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 5.4 .1.1 Part Spreading

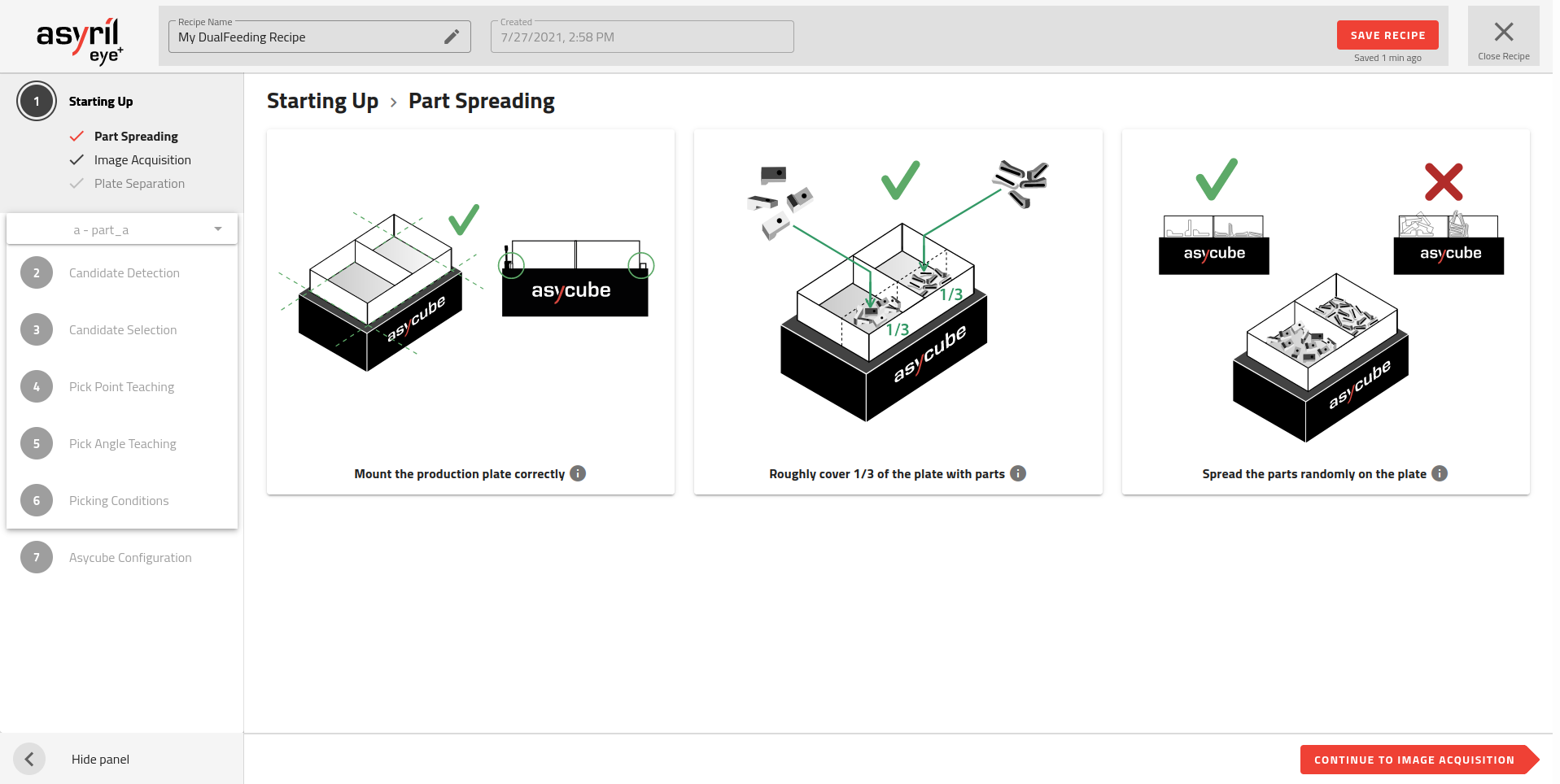

Fig. 214 Starting up - Part Spreading

Before starting, make sure that the Asycube dualfeeding production plate is correctly mounted.

Then place a reasonable number of each part on their respective side evenly distributed on the production plate. A general rule to find the appropriate part number is to have 1/3 of each side of the plate covered by parts.

Spread the parts randomly but make sure to have all possible orientations of the parts represented:

Good orientation: The orientation of the part required for the robot pickup.

Bad orientation: All other orientations of the part that are not suitable for robot pick-up.

Tip

Leave some parts in contact (a group of 2 parts is sufficient). This will ensure that groups of parts are rejected during the candidate detection stage.

1.2 Image Acquisition

This step is the exact same as with a single part recipe. For more information, please refer to 1.2 Image Acquisition.