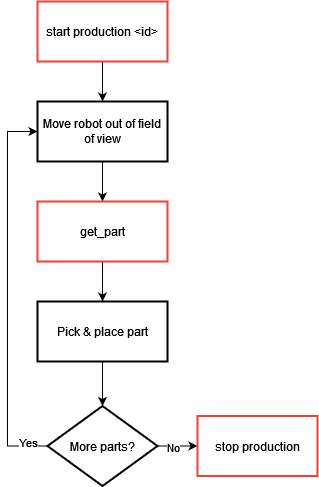

Sample program

Here we introduce an example of a program to perform a basic pick and place.

Fig. 9 Production scenario with get_part

It is necessary at this stage to have already performed the camera configuration, as well as the creation of a recipe with its hand-eye calibration.

Basic scenario - get_part

Initialization

1. Prepare the robot

Initialize robot frames and tools.

Initialize the robot gripper.

Move the robot out of the field of view.

2. Initialize the communication

Call the commands EYE_CONFIGURE with the correct IP address, port number and starting point.

3. Start EYE+ in production

Stop the current state of the EYE+ if needed and start the production with the desired recipe.

Cyclic part of robot program

4. Get the part coordinates

Call the command EYE_GET_PART to get the coordinates of the part to be picked.

These coordinates will be stored in the point P[StartPoint].

5. Check if no error occurs while requesting the part coordinates

Call the command EYE_CHECK_LAST_ERROR and check if it returns 0. If it does not, an error has occurred (e.g., a timeout).

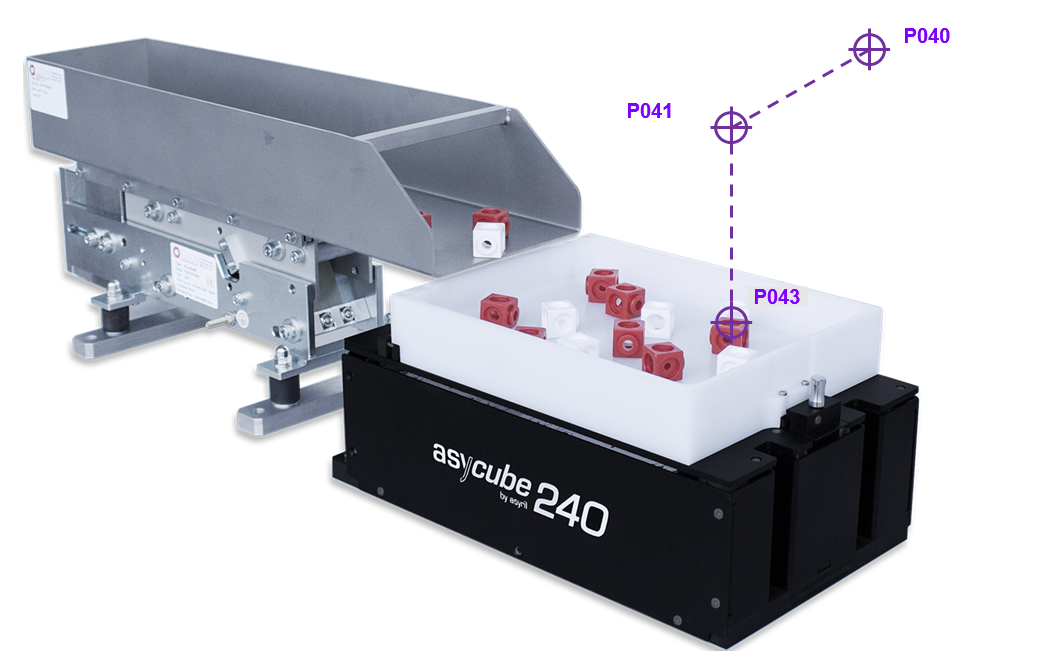

6. Calculate position

Create the needed positions:

Pick position: Copy

P[StartingPoint]toP043with the Z, RX and RY coordinates,Pick position with Z offset:

P041with a Z-offset from the pick position to make sure not to hit anything when picking the part, whether it is the Asycube or another part.

Fig. 10 Path to pick the part

7. Pick

Follow the path from P040 to P041 to P043 and pick the part with your gripper.

8. Place

Follow the path from P043 to P041 to P042 and place the part with your gripper.

Example of Yaskawa program

Here is an example of a simple pick and place in MotoSim with starting point to 300 :

NOP

'-----------------------

' Example of integration

'-----------------------

'

' Prepare your

' - User coordinates

' - Tool

' - Gripper

'

' EYE+ conf: 192.168.0.50:7171

' Reserved memory area: 300-600

CALL JOB:EYE_CONFIGURE ARGF "192.168.0.50" ARGF 7171 ARGF 300

'

' Check if no error while configuring the communication

CALL JOB:EYE_CHECK_LAST_ERROR

GETS LI010 $RV

IFTHEN LI010<>0

JUMP *stop

ENDIF

'

' Start EYE+ in production

CALL JOB:EYE_START_PRODUCTION ARGF 65447

'

' Check if no error while starting the production

CALL JOB:EYE_CHECK_LAST_ERROR

GETS LI010 $RV

IFTHEN LI010<>0

JUMP *stop

ENDIF

'

' Move out of field of view

MOVL P040 V= 10.0

'

'

CALL JOB:EYE_CHECK_LAST_ERROR

GETS LI010 $RV

IFTHEN LI010=0

' Start pick and place

'--- LOOP 20 ---

SET I298 0

WHILE I298<20

' EYE+ get_part

CALL JOB:EYE_GET_PART

'

' If no error: pick and place

CALL JOB:EYE_CHECK_LAST_ERROR

GETS LI010 $RV

IFTHEN LI010<>0

JUMP *stop

ENDIF

'

' Calculate positions

SET P043 P300

' Set Z-value

SETE P043 (3) -16500

' Set RX value

SETE P043 (4) 1790000

' Set RY value

SETE P043 (5) 0

'

' Move to approache point

SET P041 P043

SETE P041 (3) 30000

MOVL P041 V= 10.0

'

' Move on the part

MOVL P043 V= 10.0

'

' Pick the part - Gripper ON

DOUT OT#(1) ON

TIMER T=0.200

'

' Move to approache point

MOVL P041 V= 10.0

'

' Place the part - Gripper OFF

MOVL P042 V= 10.0

DOUT OT#(1) OFF

' Move out of field of view

MOVL P040 V= 10.0

INC I298

ENDWHILE

ENDIF

'

' Stop EYE+

*stop

CALL JOB:EYE_STOP ARGF "production"

'

' Check if no error while stopping the production

CALL JOB:EYE_CHECK_LAST_ERROR

GETS LI010 $RV

IFTHEN LI010<>0

'error

ENDIF

'

END