Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 5.3 .7.3 Vibration Sequence

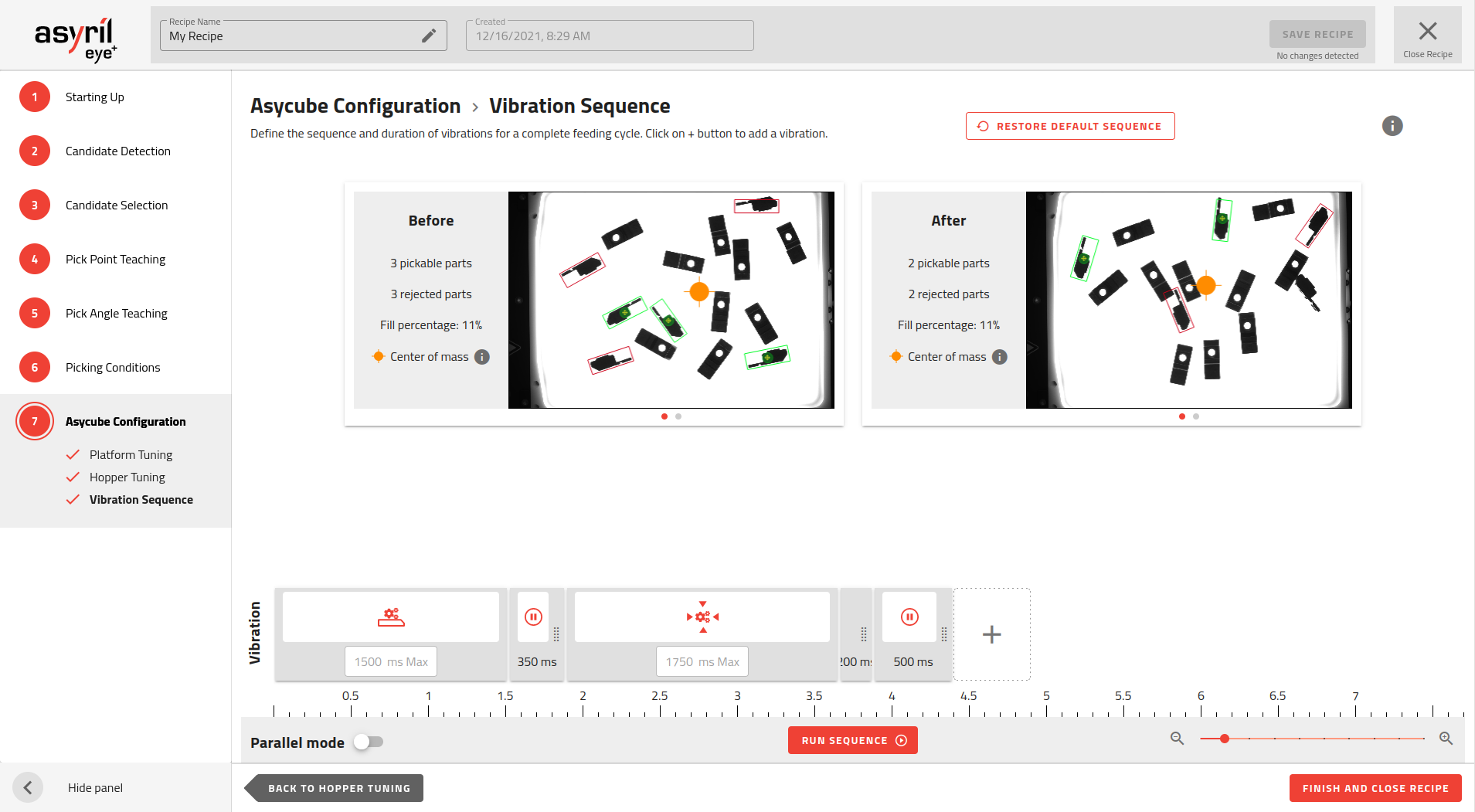

Fig. 128 Asycube Configuration - Vibration Sequence

The vibration sequence is the sequence that is executed each time there is no more available parts to pick on the Asycube. A typical sequence is most of the time composed of:

A feeding action: Fill the Asycube to be close to the optimal number of part.

A centering action: Center the parts in the middle of the Asycube.

Flip: Flip and spread the parts to avoid too much contact between each others.

Wait: Wait for the parts stabilization after the last vibration.

Vibration sequence goal is to bring enough parts well spread out in the Asycube to make it possible to detect new other pickable parts.

Feeding actions

Smart Feeding

This action should almost always be used in the beginning of a sequence. The smart feeding will automatically vibrate the hopper during a proportional time to fill the Asycube with the optimal number of parts.

The smart feeding duration depends on the initial number of parts on the Asycube. The more parts are detected, the less time the vibration takes and when the upper limit of parts on the platform is reached, the vibration duration decreases to zero. In between, the vibration duration is linearly interpolated.

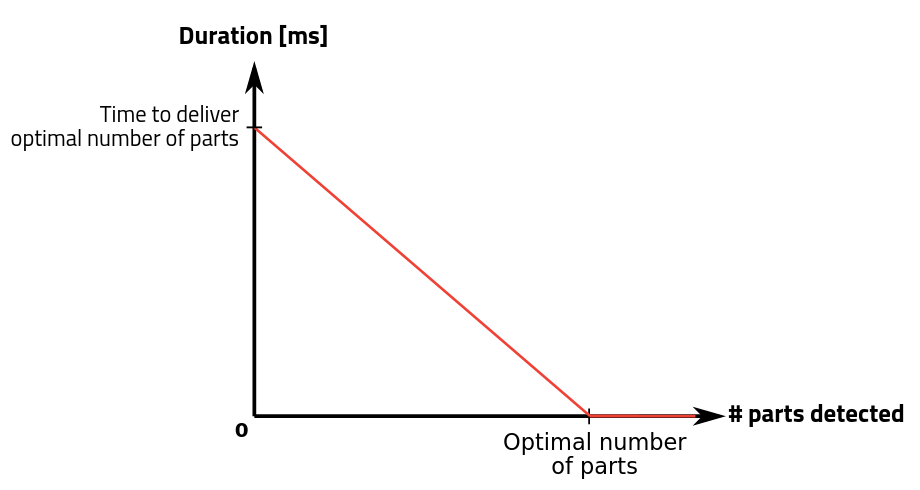

Fig. 129 Adjustment of hopper vibration duration using smart feeding

Example: Let’s suppose that the optimal number of parts has been defined at 40 in the previous step and the duration (time to obtain optimal amount) entered is 1000 ms.

In a first case, if no part is present on the platform, the effective vibration duration will be 1000 ms.

In a second case if 20 parts are detected on the platform, the effective vibration duration will be 500 ms.

In a third case where 30 parts are detected on the platform, the effective vibration duration will be 250 ms.

When 40 or more parts are detected, there will be no hopper vibration.

Hopper feeding

The standard hopper feeding will always vibrate the hopper during the same fixed duration regardless of the number of parts on the Asycube.

Important

Using this vibration in a sequence is not recommended as EYE+ will not be able to ensure that enough parts will be placed in the Asycube or worse, it could also put too many parts in the Asycube.

The advantage of this method is that the hopper vibration will always take the same known time.

Centering actions

Smart Centering

The smart centering is used to center the parts automatically. It performs the best suited vibration among left, right, backward and forward vibrations to center the parts in the middle of Asycube from any initial position.

The duration of the vibration depends on the position of the center of mass of all the parts. The duration of vibration is proportional to the duration entered to cross the platform in the 7.1 Platform Tuning step.

Fig. 130 Sequence with smart centering

Important

It is important to set the vibration duration as the time the parts need to cross the entire platform in a given direction. The effectiveness of the Smart Centering vibration depends on well-adjusted parameters.

Note

The indicated time in the interface is the maximum time this action will take. The actual vibration time will usually be shorter.

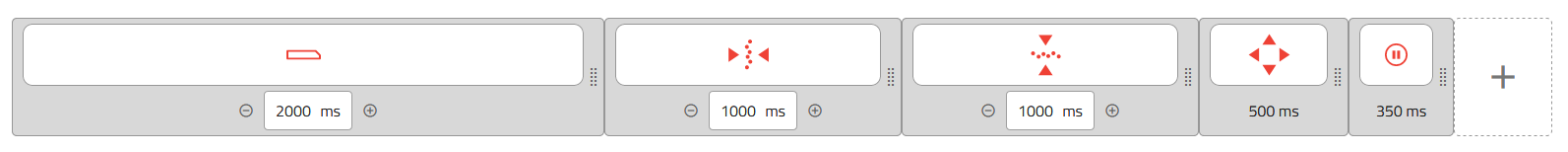

Cross and Long centering  +

+

Note

These centering movements are only available on Asycube 240, 380, 530.

The cross centering vibration brings the parts on the vertical line in the middle of the Asycube and the long centering on the horizontal line of the Asycube. If these two methods are called in succession, the parts will be centered in the middle of the Asycube. The execution could be longer than the smart centering, but the advantage is that the execution time will still be the same from one sequence to the other during production.

Fig. 131 Sequence with cross and long centering

Other actions

All the other actions correspond to the individual movements that you tuned in the 7.1 Platform Tuning step.

Basic displacements: left, right, backward, forward

These displacements can be used to move the part in a specific direction. These movements can be very useful in the case of using a specific plate (holes, grooves) to orientate the parts in a more favorable position for robot pickup.

Flip

The flip vibration is used to flip the parts in order to avoid too much contact between each other and to flip the parts orientation. It is strongly recommended to use this action in your sequence after any centering action.

Wait

It is used to wait for the parts stabilization.

Important

You should always end your sequence with a stabilization time. This will ensure that the parts are not moving during the image acquisition phase. Having no or too short stabilization time could lead to picking issues.

Tip

The stabilization time can be lowered by using an anti-rolling vibrating plate.

Parallel mode

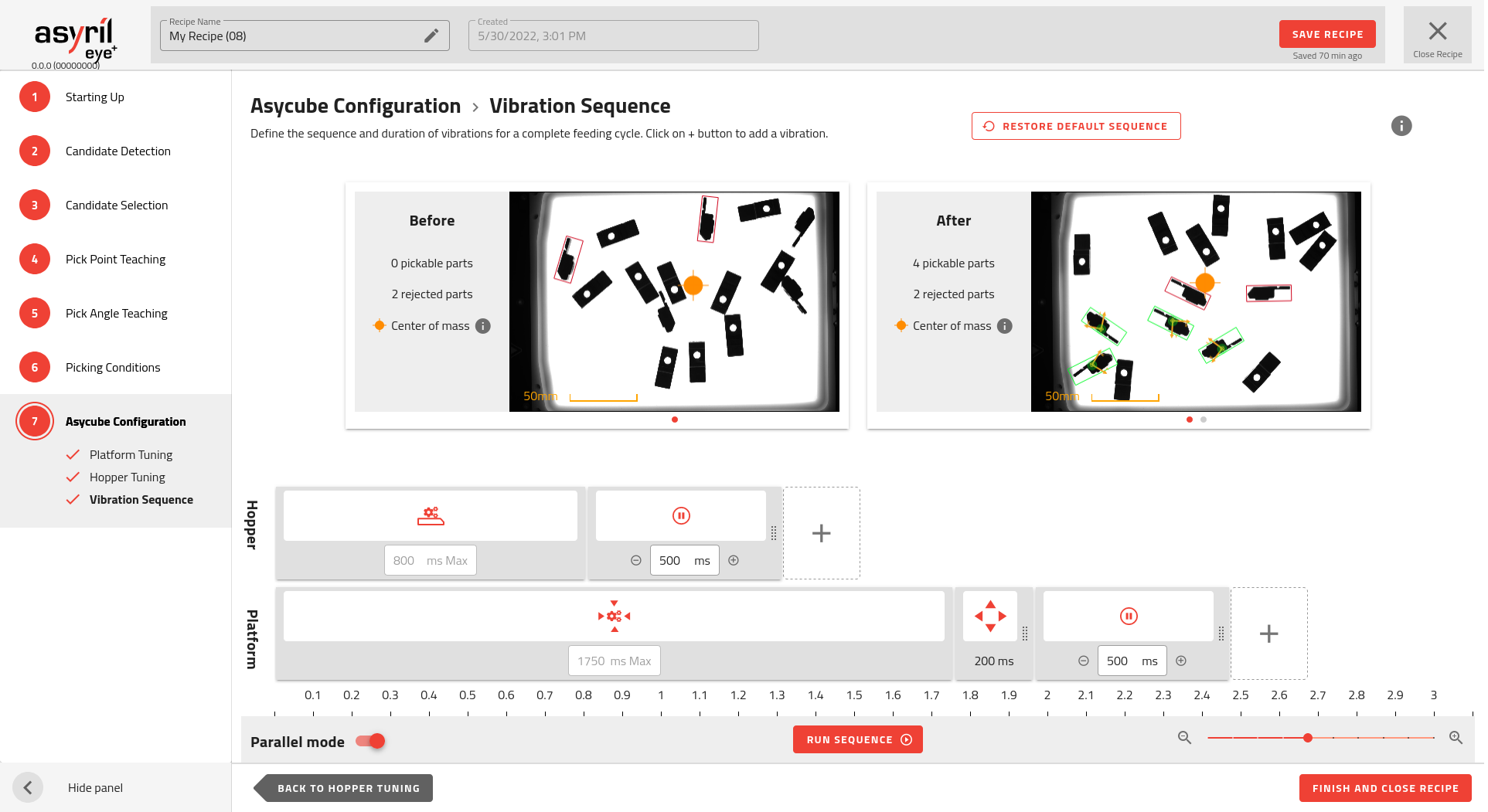

Fig. 132 Asycube Configuration - Hopper and Platform subsequences

If cycle time is critical, you can improve it using parallel mode. In this mode, the original sequence is split into two subsequences that will run in parallel:

A hopper subsequence: Allows you to use feeding actions or wait.

A platform subsequence: Allows you to use platform actions or wait.

You can enable parallel mode using the ![]() switch. Once enabled, hopper actions will be moved to a new

dedicated subsequence while platform ones will be assigned to a platform subsequence.

switch. Once enabled, hopper actions will be moved to a new

dedicated subsequence while platform ones will be assigned to a platform subsequence.

Note

Wait actions will be duplicated between the hopper and platform subsequence when you enable parallel mode.

Test your vibration sequence

You can test your vibration sequence by clicking on . It will display an image of the Asycube before and after the vibration with some information on:

the number of pickable parts

the number of rejected parts

the filling percentage is the ratio of part compared to background in percent

The orange dot represents the center of mass which is the computed gravity center of all parts on the Asycube. The target of a smart centering action is to move this center of mass to the middle of the Asycube.

Tip

Test your sequence with different scenarios (no parts onto the Asycube but hopper filled, optimal amount of parts on the feeder but all accumulated in a corner, etc…). At this point you should also be able to evaluate the cycle time your application will be able to reach by measuring the number of parts available in average after running a sequence.

Once you are satisfied with your vibration sequence, you can close the recipe using on the bottom. You will come back to the Recipes list and will find your recipe in the list.