Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 5.3 .Camera and lens

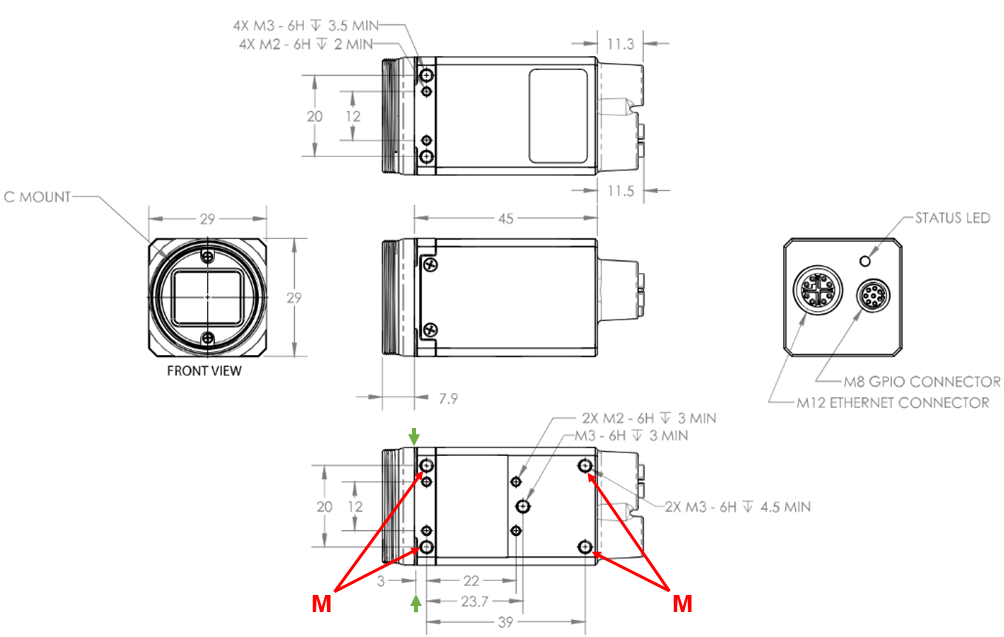

Dimensions

The camera can be fixed using the four M3 mounting holes (labeled M on Fig. 17).

Fig. 17 Camera dimensions; M= Mounting holes

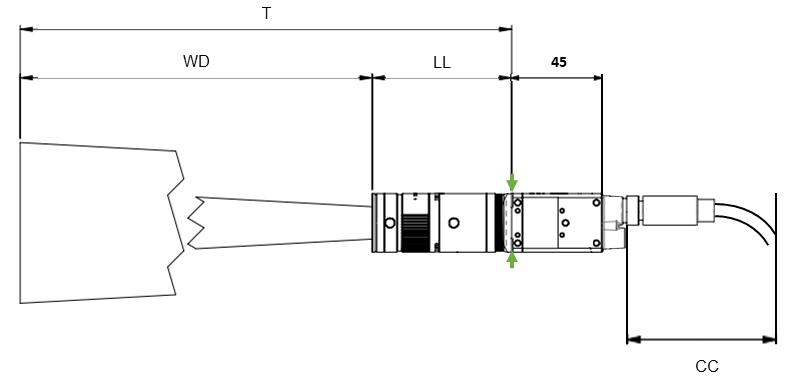

Depending on your Asycube size and your working distance, different lens may be used. Main dimensions of the different vision kits (See Fig. 18) are summarized in Table 6 and in Table 7

Fig. 18 Camera with cable connected dimensions; T= Total length; WD = Working distance; LL = Lens length; CC = Cable connector + cable folding length

Characteristic |

Value |

|---|---|

Weight |

67g |

Dimensions |

29 x 29 x 64.4 mm |

Cable connector + cable folding (CC) |

120 mm |

Asycube |

WD: Working distance [1] |

LL: Max lens length [2] |

TL: Total length |

Lens weight |

|---|---|---|---|---|

Asycube 50 |

Short: 390mm |

69.02 mm |

459.02 mm |

0.08 kg |

Long: 560mm |

92.88 mm |

652.88 mm |

0.22 kg |

|

Asycube 80 |

Short: 580mm |

69.02 mm |

649.02 mm |

0.08 kg |

Long: 850mm |

92.88 mm |

942.88 mm |

0.22 kg |

|

Asycube 240 |

Short: 790mm |

57.78 mm |

847.78 mm |

0.06 kg |

Long: 1070mm |

56.90 mm |

1126.90 mm |

0.07 kg |

|

Asycube 380 |

Short: 810mm |

57.30 mm |

867.30 mm |

0.08 kg |

Long: 1260mm |

57.78 mm |

1317.78 mm |

0.06 kg |

|

Asycube 530 |

Short: 900mm |

63.48 mm |

963.48 mm |

0.09 kg |

Long: 1260mm |

57.30 mm |

1317.30 mm |

0.08 kg |

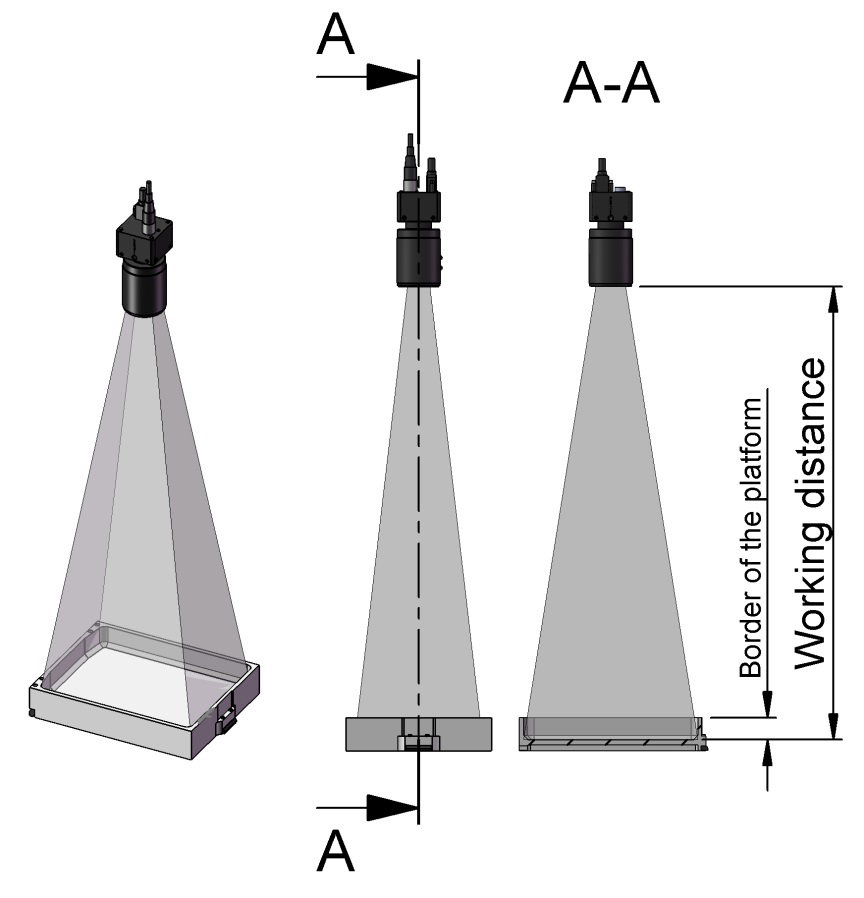

Fig. 19 Working distance

Mounting the camera and the lens

Unpack the camera and the lens. The lens is already mounted on the camera.

Fix the camera using the four M3 mounting holes (labeled M on Fig. 17).

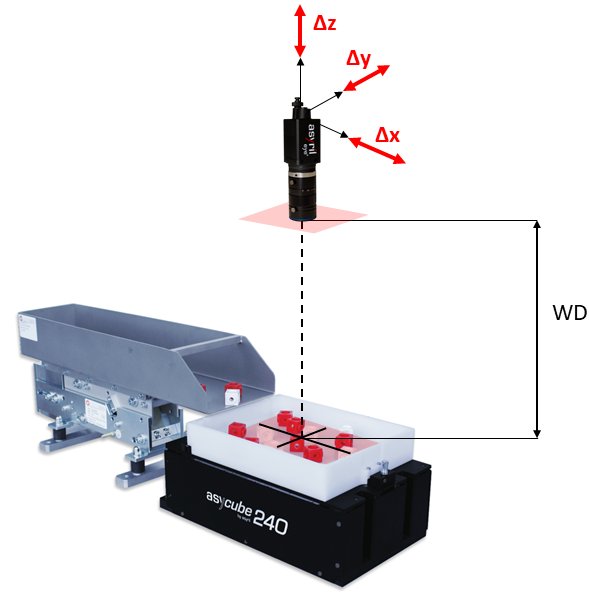

Camera positioning

Camera must be placed orthogonal to the Asycube and above its center.

Important

The orthogonality between the camera and the Asycube is critical for accurate part detection. Particular care must be taken at this stage of installation.

Distance between the front face of the lens and the Asycube plate has to correspond to the working distance (see Table 7).

Make sure that the field of view is defined as the inner edge of the plate frame. The EYE+ logo must be oriented opposite to the Asycube connectors (Fig. 20).

Important

We recommend you design the camera mounting so that it can be adjusted in x, y and z. Make sure that the camera position can be adjusted mechanically with a tolerance of -10mm/+30mm in z and -10mm/10mm in x and y.

Fig. 20 Camera positioning; WD = Working Distance