Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 5.3 .7.1 Platform Tuning

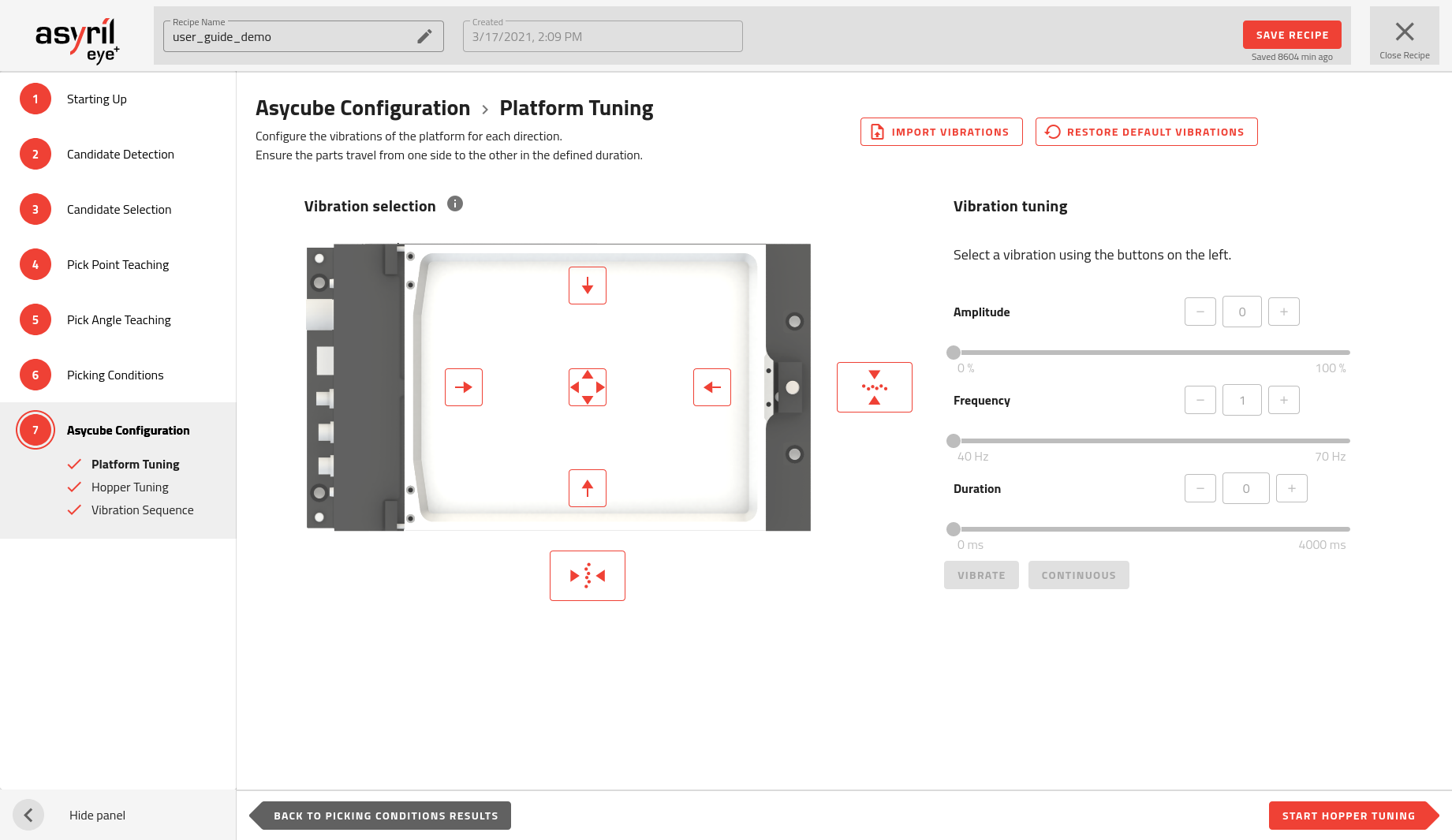

Fig. 136 Asycube Configuration - Platform Tuning

Depending on the Asycube size, five or seven vibrations must be correctly configured.

For all Asycubes: five standard vibrations: left

, right

, right  , backward

, backward  , forward

, forward  , flip

, flip

- For Asycubes 240, 380, 530: Two additional centering vibrations:

cross-centering

, long-centering

, long-centering

Tip

If you already have tuned the vibration parameters for a similar part, you can use to copy the vibration parameters from another finished recipe.

Tune the amplitude, frequency and duration

Each vibration must be tuned independently by clicking on the corresponding vibration icon and modifying its associated parameters on the right side of the window.

1. Amplitude and frequency

For each vibration, define the optimal amplitude and frequency. Click on the button to test the tuning. You can also use the continuous mode to tweak the amplitude or the frequency while the selected vibration is running, once finished, simply stop the vibration using the button.

Flip vibration: Find the amplitude and frequency allowing to flip the parts orientation on the Asycube. Increasing the amplitude makes the parts jump higher.

All other vibrations: The optimal amplitude and frequency produces a fast and smooth displacement of the parts.

Tip

For all the platform vibrations except the Flip, Cross and Long axis centering the frequency is usually the same. Once a suitable frequency is found for the displacement of the parts on the platform, it generally suits the other displacements as well.

Tip

All Asycubes are delivered with their own set of default parameters that provide a very good starting point for your tuning. Try the default amplitudes and frequencies first, and then adjust these parameters depending on your observations.

Note

High energy mode: For Asycube 50 or 80, the high energy mode can be used to increase the vertical amplitude for each vibration. This mode can be particularly useful to move parts on a specific plate with holes, or to flip rather large parts for example

2. Duration

Once you have founded the optimal amplitude and frequency to guarantee a good behavior of the parts, set the duration it takes for your parts to move from one side of the Asycube to the other.

- For standard vibrations (except Flip): Put the parts on the opposite side of vibration and start the vibration by

clicking on . The Asycube vibrations should end when the parts reach the other side of the Asycube. If not, adapt the duration accordingly until this is true.

- For centering vibrations: Put half of the parts on each side of the centering line and start the vibration by

clicking on . Adjust the duration so that Asycube vibrations end when the parts reach the middle of the Asycube.

Important

Smart centering: It is critical to set the right duration of vibration for each direction. This parameter will be used as a reference when separating the parts during production (see “smart centering action” in the vibration sequence)

Note

If you want to restore the default vibrations, click on .

Adjust vibration direction

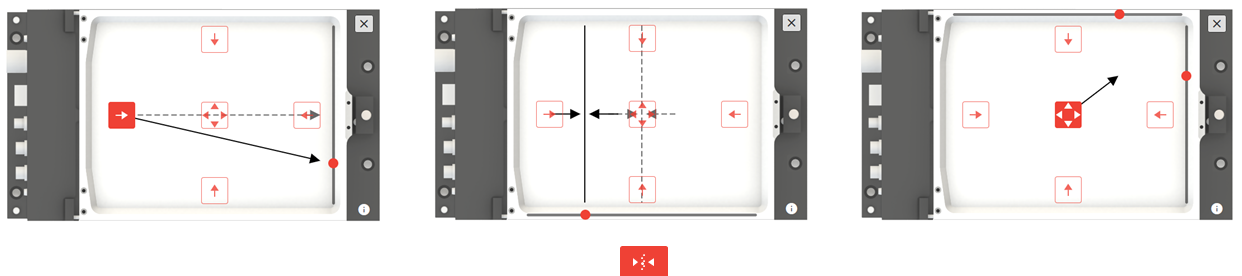

If the parts do not move perfectly in the desired direction, you can correct the displacement error with the sliders on the sides.

Start the vibration without correction and observe the parts direction.

If the direction is not as expected, move the slider to add an offset in the opposite direction. For example, if at the end of the vibration the parts are shifted to the left when they are only supposed to move forward, you have to add an offset to the right in order to obtain a perfect forward movement (see left illustration in Fig. 137).

Start the vibration again to check if the correction yielded the expected result. If not, adjust the arrow until you observe the expected direction.

Fig. 137 Vibrations correction

Important

Adjusting the directions properly will avoid accumulation of parts on a side or a corner during production. It is important to adjust these directions carefully.