Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 5.3 .7.2 Hopper Tuning

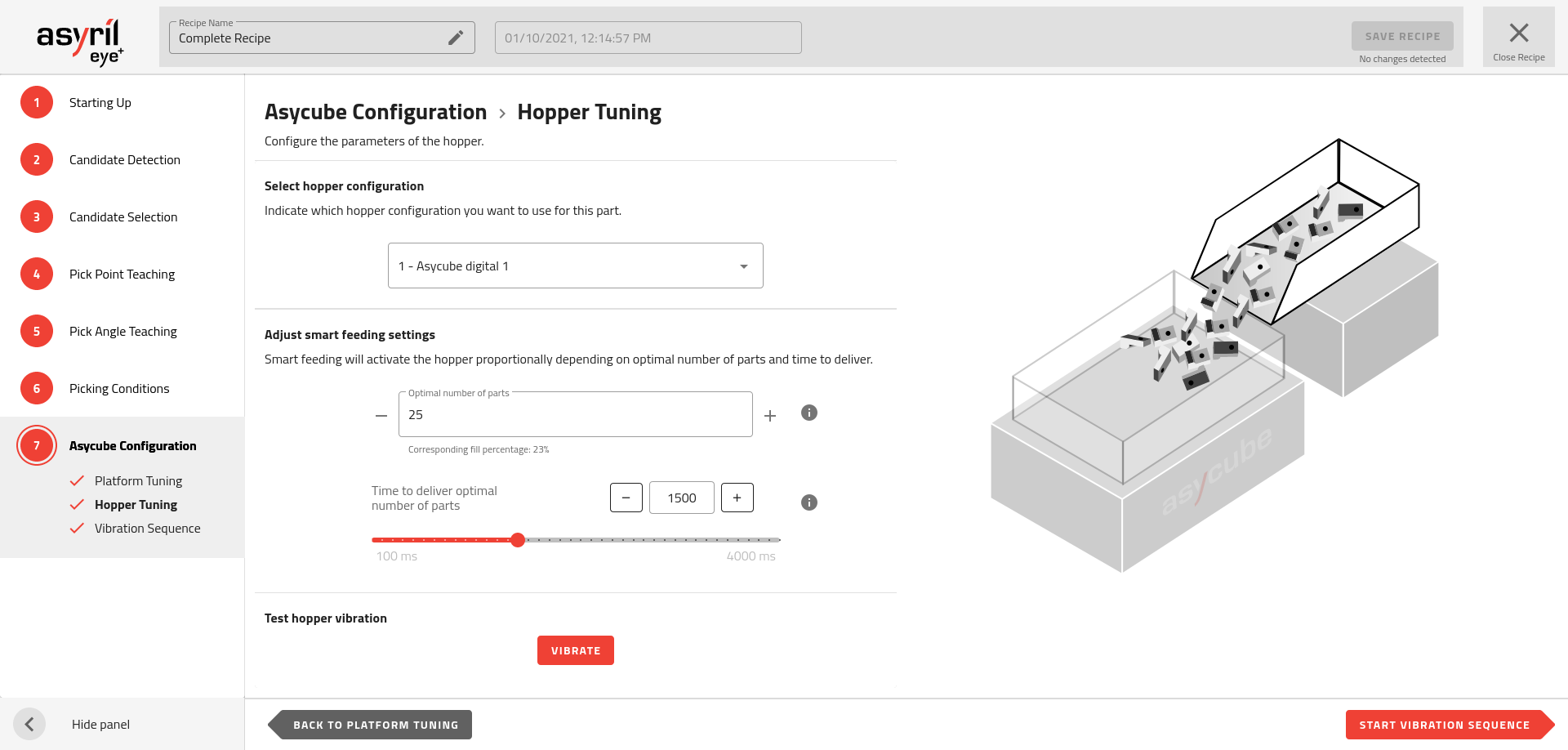

Fig. 138 Asycube Configuration - Hopper Tuning

The hopper vibration must be correctly configured to feed a regular amount of parts on the Asycube plate. You must find a good balance between:

A slow flow that takes too much time to fill the right amount of parts onto the Asycube.

A fast flow that risks overfilling the Asycube.

Adjust hopper/output parameters

Depending on the Asycube, a hopper is either integrated (Asycube 50 and 80) or not (Asycube 240, 380 and 530).

Asycube 50/80

The Asycube 50 and 80 have an integrated hopper to feed the necessary number of parts onto the platform in order to obtain at each cycle an acceptable number of parts available for picking by a robot.

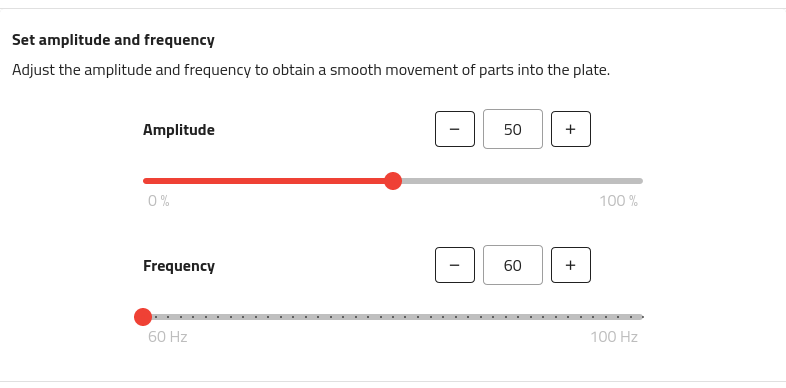

Fig. 139 Amplitude and Frequency tuning for Asycube 50/80

Amplitude: Amplitude of the signal sent to the actuator and defined as the percentage of the maximum amplitude

Increasing the amplitude makes the parts jump more.

Range: 0-100%

Frequency: The frequency of the signal sent to the actuator

Parts react more to certain frequencies depending on factors such as their mass, geometry or rigidity.

Range: Typically 60-80Hz

Asycube 240/380/530

The Asycube 240, 380 and 530 require a dedicated hopper to feed the parts in production. The hopper must be configured in the hopper configuration as this configuration will be available for all recipes.

The hopper configuration can be chosen from the list of available configurations. By default, the first available configuration will be selected.

Important

When you have an Asycube 240 with a purging system, the second output on the Asycube will be needed to operate that system, meaning you will not be able to use it for a hopper.

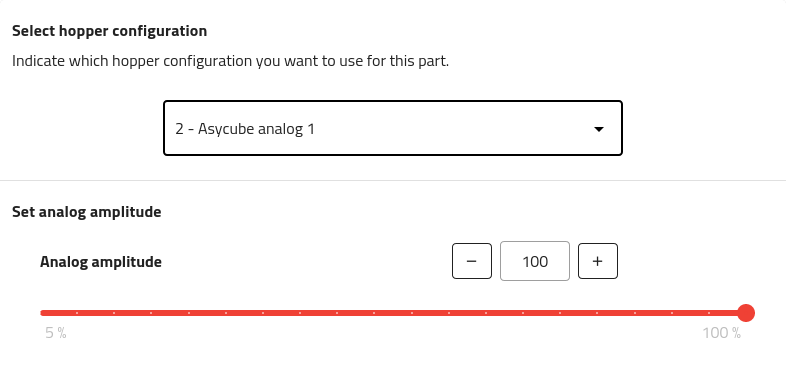

If the chosen configuration is either an Asyfill or an analog output, a slider will appear allowing you to set the amplitude (Fig. 140).

Fig. 140 Amplitude slider appearing when selecting an Asyfill or a hopper configuration with an analog output

Tip

For analog mode, you can then choose the intensity in percentage: 100% corresponds to 10 V output.

Adjust Smart feeding settings

The following parameters will be used to parameterize the Smart Feeding in the vibration sequence.

Set the optimal number of parts

To know what is the optimal number of parts, place some parts in the Asycube randomly distributed and stop adding parts when they start to be too close to each other. Count the parts on the Asycube, this is your optimal number of parts.

Input this number n in EYE+ Studio. This number is necessary for smart feeding.

Important

The optimal number of parts parameter will be used as a reference when activating the hopper during production (see Smart Feeding in the vibration sequence)

Set the duration of vibration

The number of parts delivered directly correlates to the duration and amplitude of the hopper vibrations. This must be set by trial and error.

First remove all the parts from the Asycube and fill the hopper with parts.

Important

The hopper must be filled as it would be in production.

Start the hopper vibration by clicking on .

Count the parts that fall onto the Asycube. If it is not the optimal number of parts, adapt the duration of vibration and repeat the steps until you get the right amount of parts on the Asycube.

Note

If the time to deliver the optimal number is too long, you may increase the hopper vibration amplitude to increase the speed at which the parts move in the hopper, and then adjust the duration again.

Important

Under standard operation, you will have 4 possible outputs to choose from to plug your hopper into the system. When you have an Asycube 240 with a purging system however, the second output on the Asycube will be needed to operate that system, meaning you will not be able to use it for a hopper. The option will then not be listed as an available output for the hopper. Additionally in this case, any recipe using the output 2 (e.g. imported from another system) will not be valid for production until you select a different output.

Important

The behavior of the smart feeding action is influenced by the region of interest used by the system. Using a custom region of interest can hence have an effect on this action.